the design by Diana Salvador promotes collective well-being while minimizing carbon footprint

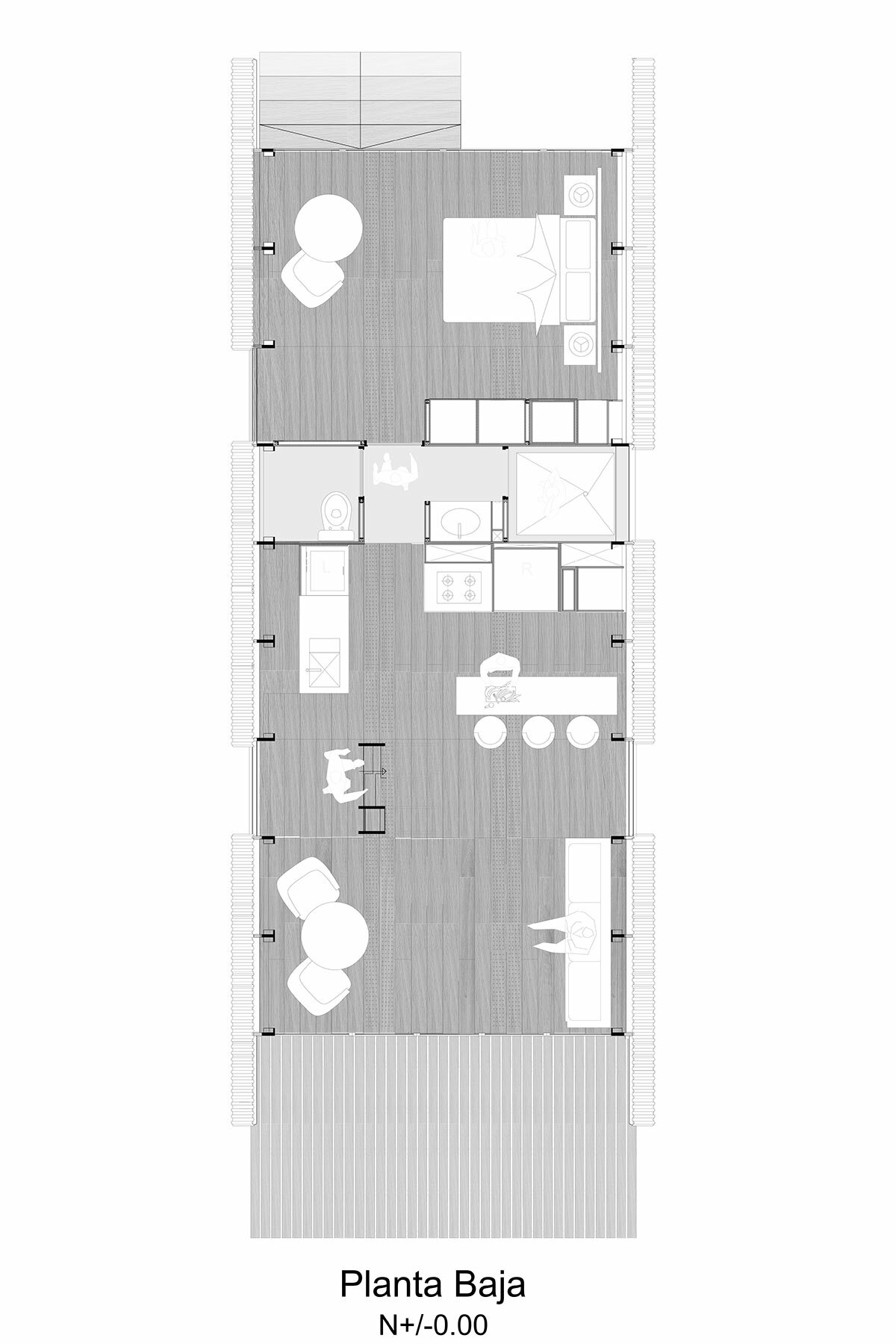

plywood makes up the structure, interior walls, furniture, and ceiling

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

'I wanted to present the building as a new landscape, embedding it into the chinese environment to create the experience of walking through the lake,' the japanese architect tells designboom.

atelier xi designs a library in a flower field as a cluster of geometric volumes, resembling faceted fragments of rock.

connections: +1960

UNStudio's ferris wheel will take shape with two intersecting rings with 64 capsules, each accommodating 20-25 visitors to seoul.

connections: +520

the center is a haven for wellbeing, child care, and interaction among the elderly in higashikawa.

images ©

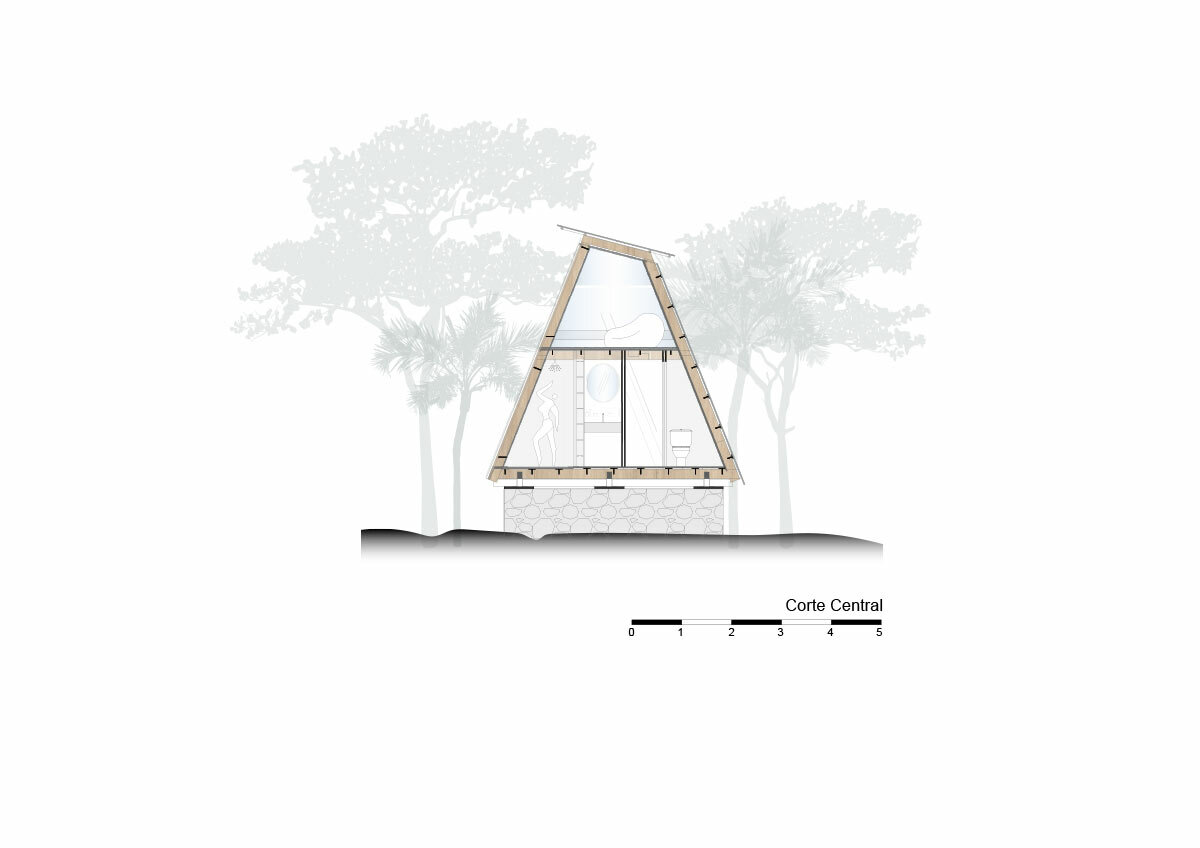

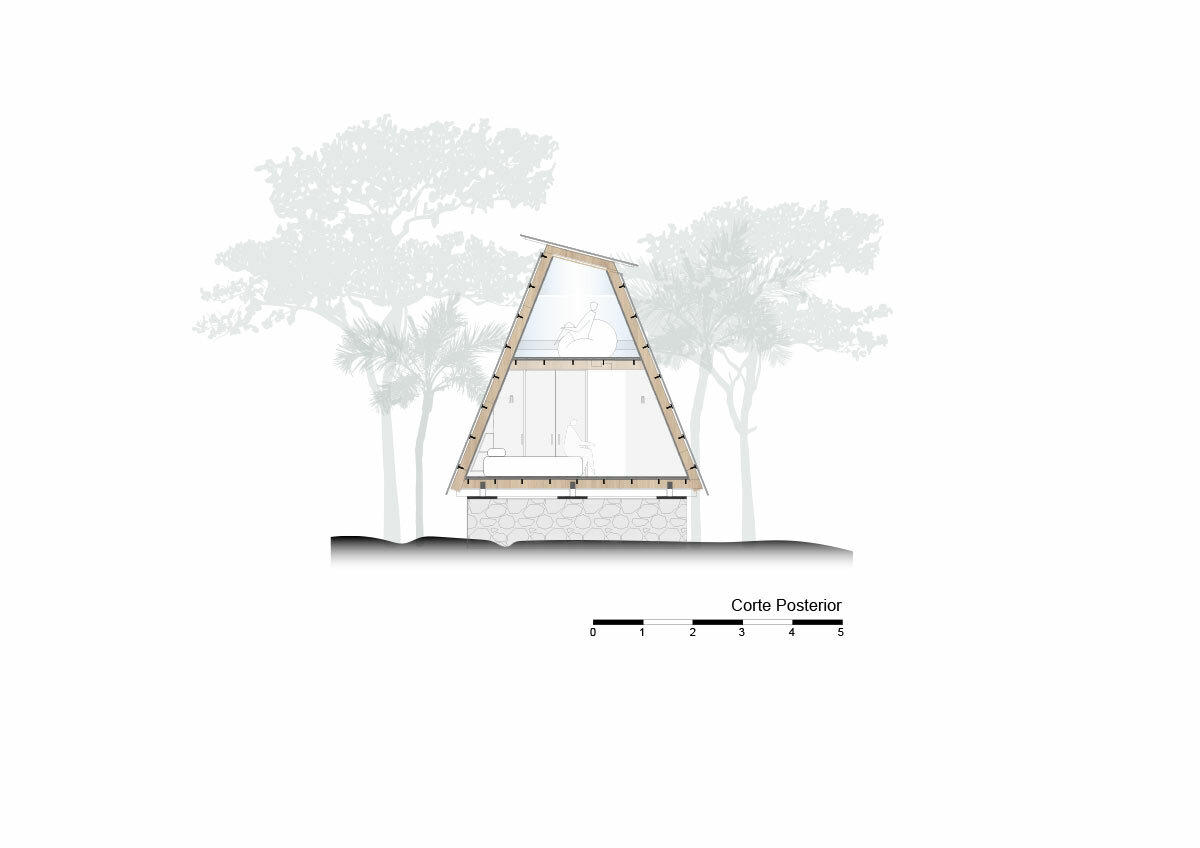

images ©  to minimize concrete use, gavions were employed as foundations

to minimize concrete use, gavions were employed as foundations

the home is built of wood, stone, metal, glass, and PVC

the home is built of wood, stone, metal, glass, and PVC